5 Reasons to Choose HDPE Drainage Pipes for Your Next Project

Selecting the right drainage pipes is crucial for any construction and infrastructure project. Poor choices lead to costly repairs and system failures cause major headaches. HDPE drainage pipe is the answer. This specific type has gained impressive popularity. HDPE pipes offer outstanding performance advantages and their sustainability benefits make them preferred in modern projects.

5 Reasons to Choose HDPE Drainage Pipes

Drainage systems prevent water damage and ensure proper flow management. HDPE drainage pipe products have transformed this essential component. They, hence, deserve serious consideration. The following are 5 reasons to choose them:

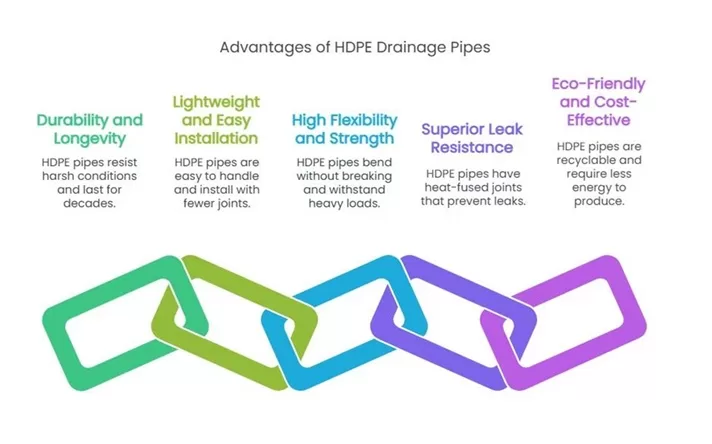

1. Exceptional Durability and Longevity

HDPE pipes excel in harsh environments. They resist chemical exposure and pipes don’t rust or corrode. They maintain integrity in extreme temperatures. Most HDPE black drainage pipe systems last 50-100 years. This longevity reduces maintenance costs and fewer replacements save money long-term.

The pipes also withstand UV radiation without degrading, making them suitable for above-ground applications too. Their abrasion resistance is remarkable and they handle high-velocity water flow without wearing down. The material doesn’t become brittle with age, either.

2.Lightweight and Easy Installation

HDPE pipes weigh less than concrete or metal. This means crews can handle them without heavy machinery and installation requires fewer workers. The pipes join through heat fusion, hence creating seamless connections. No weak points exist in the HDPE drainage pipe system.

These attributes result in the installation costs dropping significantly. HDPE pipes can be custom-fabricated on-site. This reduces the need for specialized fittings. Longer pipe sections mean fewer joints overall. Each rainwater drainage pipe joint eliminated is a potential leak prevented.

3. High Flexibility and Strength

HDPE pipes bend without breaking and absorb ground movement. Their flexibility allows for trench-less installation. These pipes handle heavy soil loads and maintain shape under pressure. This makes them ideal for shifting soils. They return to their original form after compression. This self-recovery feature of gutter drainage pipe systems prevents permanent deformation.

The impact resistance of HDPE drainage pipe types exceeds that of clay or concrete. This results in accidental strikes during excavation rarely causing damage. They perform well under freezing conditions as expansion from ice formation doesn’t crack them.

4. Superior Leak Resistance

Leakage ruins effective drainage systems. HDPE pipes feature heat-fused joints. No gaskets or seals create weak points. Water cannot escape through connections and the material itself blocks liquids. This HDPE drainage pipe performance ensures decades of proper function.

Even high-pressure applications remain secure and reliable with these pipes. Root intrusion is virtually eliminated as trees cannot penetrate the solid pipe walls. Chemical resistance prevents the deterioration of joints. Not to mention acid rain and soil contaminants have no effect either.

5. Eco-Friendly and Cost-Effective

HDPE pipes have impressive environmental credentials. They are 100% recyclable, and their manufacturing requires less energy than alternatives. HDPE drainage pipe transportation creates smaller carbon footprints. Traditional materials can’t compete economically.

HDPE pipes contain no harmful chemicals or toxins. Their smooth interior prevents buildup and improves flow efficiency. Energy costs decrease during operation and production uses fewer raw materials. Last but not least, local manufacturing options often exist, hence reducing shipping distances and associated emissions.

LESSO HDPE Drainage Pipes: A Dependable, Long-Term Solution

The seasoned brand LESSO has built a stellar reputation in the HDPE drainage pipe manufacturing field. The company’s portfolio spans from piping to home furnishings, and it serves markets worldwide. LESSO’s HDPE drainage pipe systems represent both quality and innovation. These systems work in multiple configurations and integrate with modern construction methods. Some of their unique features include:

✔ Corrosion Resistance

LESSO’s HDPE drainage pipe solutions withstand various chemical agents and electrochemical corrosion. They perform reliably even in aggressive environments. This PVC for drainage pipes protection eliminates a common failure point in drainage systems.

✔ Long Lifetime

Under normal circumstances, LESSO HDPE drainage pipe systems last at least 50 years. They maintain peak performance throughout their extended service life. This reduces replacement costs significantly.

✔ Good Resistance to Underground Movement or Ground Load

The HDPE same-floor drain pipes have excellent flexibility with elongation reaching 350% before breaking. They resist non-uniform settlement that would damage rigid pipes. This makes them ideal for areas with unstable ground conditions.

✔ Good Resistance Against Rapid Crack Propagation

LESSO’s HDPE drainage pipe products maintain structural integrity even under sudden stress. They prevent catastrophic failures that plague less resilient materials. This adds a critical safety factor to infrastructure projects.

Conclusion

HDPE drainage pipe systems offer compelling advantages. They combine durability with easy installation and resist leaks effectively. They handle ground movement with ease. They also provide ecological benefits. Recyclability reduces their environmental impact. The reputed brand LESSO is a premier provider of quality HDPE drainage pipes. These solutions feature corrosion resistance, long lifetime, light weight, and more. Visit the company’s website to explore its complete product range. Your project deserves the industry’s best drainage system solutions.