Technology

The Power of Rapid Prototyping in Automotive Engineering

The automotive industry has always been at the forefront of technological innovation, constantly striving to create vehicles that are safer, more efficient, and more appealing to customers. One of the key drivers behind this progress is the utilization of rapid prototyping in automotive engineering. Rapid prototyping technologies have revolutionized the product development cycle, enabling automakers to bring new ideas from concept to reality faster than ever before. In this article, we will explore the significance of rapid prototyping in the automotive sector, the various technologies employed, and their diverse applications.

The Need for Rapid Prototyping in Automotive Engineering

The traditional process of developing automotive products involved multiple stages of prototyping, each of which required considerable time and resources. From sketching initial concepts to fabricating physical prototypes, the process was time-consuming and often expensive. However, in today’s highly competitive market, speed and agility are critical to success. Rapid prototyping services address these challenges by expediting the product development cycle and mitigating risks associated with traditional methods.

Accelerating product development cycles in the automotive sector:

Rapid prototyping significantly reduces the time required to transform a concept into a tangible prototype. Designers and engineers can now quickly iterate through multiple design variations, allowing them to fine-tune and optimize their ideas more efficiently. This accelerated process enables automakers to bring new vehicle models and components to market much faster, gaining a competitive edge in the industry.

Reducing costs and risks associated with traditional prototyping methods:

Developing physical prototypes using traditional methods, such as molding and casting, can be expensive, especially when multiple iterations are required. Rapid prototyping technologies, like 3D printing and CNC machining, eliminate the need for expensive tooling, making the process more cost-effective. Moreover, identifying design flaws and making improvements early in the development cycle minimizes the risk of costly errors in later stages of production.

Meeting customer demands for faster innovation and customization:

In today’s consumer-driven market, customers expect continuous innovation and personalized products. Rapid prototyping allows automakers to respond quickly to changing customer preferences and market trends. It enables the creation of customized vehicle features and accessories, providing customers with a more tailored and engaging experience.

Rapid Prototyping Technologies in Automotive Engineering

Additive manufacturing (3D printing) for concept models and functional prototypes:

3D printing has emerged as one of the most transformative technologies in automotive engineering. It allows designers to create complex geometries that were previously impossible with traditional manufacturing techniques. Additive manufacturing enables the production of concept models for design visualization and functional prototypes for testing and validation. It also facilitates the creation of lightweight components, contributing to overall vehicle weight reduction and fuel efficiency.

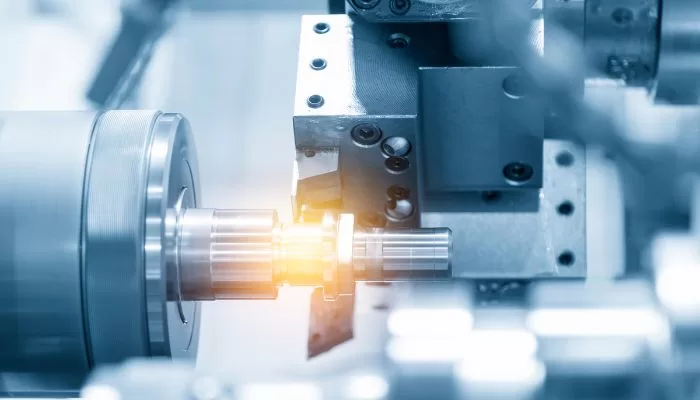

Computer Numerical Control (CNC) machining for precision prototypes:

CNC machining is another vital rapid prototyping technology widely used in automotive engineering. It is ideal for producing high-precision prototypes from various materials, including metals and plastics. CNC machines can accurately replicate the final product’s dimensions and surface finishes, making them suitable for testing and functional evaluation.

Vacuum casting and injection molding for small-scale production and testing:

Vacuum casting and injection molding are particularly useful when small-scale production or testing is required. Vacuum casting allows for the creation of limited batches of parts using silicone molds, which can closely mimic the final product’s characteristics. Injection molding, on the other hand, is used to produce larger quantities of prototypes using thermoplastic materials, providing a cost-effective solution for testing and validation.

Applications of Rapid Prototyping in Automotive Engineering

Conceptual design and visualization of new vehicle models:

Rapid prototyping enables designers to transform their ideas into tangible 3D models quickly. This allows stakeholders to visualize and evaluate the aesthetics and ergonomic aspects of new vehicle designs. Early-stage prototyping also facilitates collaboration between design and engineering teams, streamlining the development process.

Functional prototypes for testing and validation of automotive components:

Functional prototypes created through rapid prototyping technologies undergo rigorous testing to ensure their performance and durability. By identifying potential flaws and weaknesses early on, engineers can make informed design improvements before moving to the production stage, thus saving time and resources.

Customization and personalization of vehicle features and accessories:

Customers now demand more personalized products, and rapid prototyping empowers automakers to cater to these individual preferences. From custom dashboard trims to personalized exterior accents, rapid prototyping makes it possible to offer a wide range of customized options without compromising on production efficiency.